2016 FORBES DIAMONDS

The aim of the Forbes’ Diamonds ranking is to recognize companies that are characterized by high quality management, professionalism and dynamic development, as well as a very good quality of its products. Companies that increase their worth the quickest land on the Forbes Diamond list. Data used for the evaluation include, among others, sales, net income, value of fixed assets, of the inventories, receivables and capital investments.

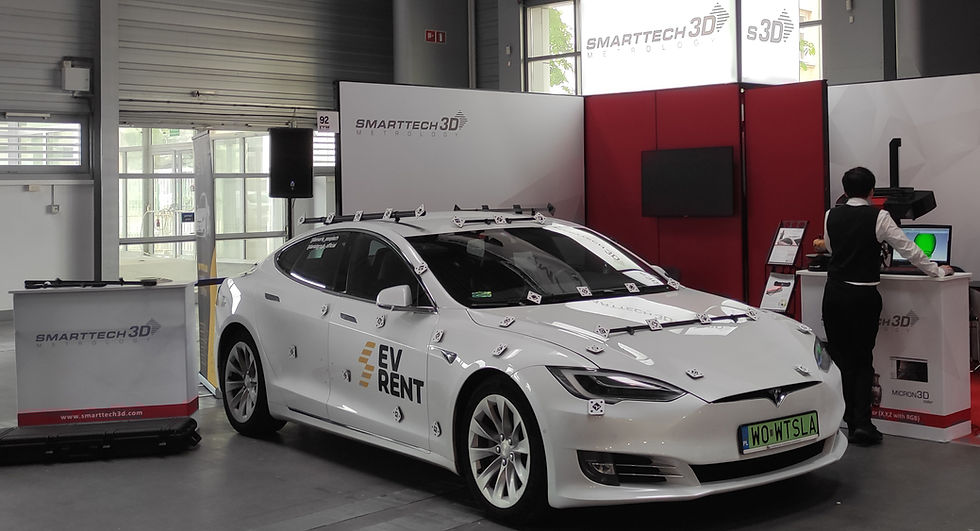

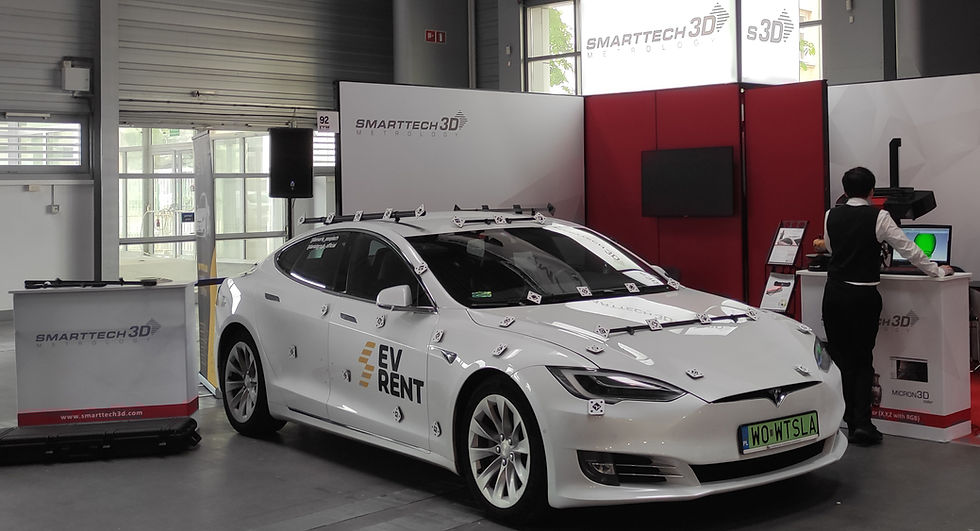

SMARTTECH3D photogrammetry is a portable coordinate measuring system based on digital photographs. It creates a digital map of markers placed on the object, which can be used for direct quality control or combined with optical full-field measurement. The system is designed for referencing 3D scanners in high-end industrial applications for large objects. Thanks to its full integration with SMARTTECH3D scanners, it enables users to scan crucial elements of large objects with high accuracy within the same coordinate system.

Incorporating photogrammetry into the 3D scanning process allows for the combination of high-resolution scanning with overall dimensional quality control while reducing the time required for optical scanning by focusing on critical points of the scanned part.

Typical usage examples:

-

Marker mapping for high-resolution 3D scanning of large objects

-

Point-to-point stand-alone quality assurance for large objects

-

Assembly control in the automotive, shipbuilding, and steel construction industries

Advantages of SMARTTECH3D Photogrammetry

-

Easy to carry: System weight is approximately 5 kg.

-

Versatile usability: Effective in bright daylight as well as on dark objects.

-

High precision: Accurate measurements for objects up to 20 m and beyond.

-

Shock-resistant: Resistant to shocks and vibrations.

-

Temperature resistant: Operates reliably across a wide range of temperatures.

Accuracy confirmed by independent authorities

Both the photogrammetry and 3D scanning processes are evaluated according to the VDI/VDE 2634 standard. The base accuracy of the photogrammetry map reaches 92 μm, while the precision of 3D scanning, depending on the model of the used scanner, can reach up to 10 μm, providing numerous application possibilities.

Photogrammetry process – how is it done?

Photogrammetry is based on high-resolution photos taken of the measured object with specially designed markers and scale bars. These images serve as input data for calculations to obtain a precise marker map of the object. The first step of the process requires the user to place self-adhesive or magnetic markers and scale bars on the object. The second step involves taking several dozen photos from different perspectives, depending on the size and complexity of the project. The gathered data is then processed in SMARTTECH3Dmeasure software to create a map of markers. This map can be directly used to perform measurements and quality checks in applications where point-to-point measurements are sufficient. For further analysis, the user can 3D scan which will be automatically fitted onto the marker map.

The highlight of the system is particularly evident when it is used as an additional module for our 3D scanners. The metric marker map created using photogrammetry is compatible with point clouds obtained from our 3D scanners. This compatibility allows for the integration of high-resolution results from 3D scanning into the created marker map. All data is placed within a single coordinate system, enabling comprehensive quality control of the entire large-sized object (marker map) and detailed analysis of selected fragments (3D scan).

SMARTTECH3Dmeasure

The SMARTTECH3Dmeasure software, with an active photogrammetry module, guarantees full integration of the photogrammetry and optical scanning processes in a single software platform. Additionally, it provides users with tools for performing further quality control based on a given reference CAD model.

Quality Control Tools

Based on customer needs, the software is equipped with essential tools for quality control, such as:

-

A color deviation map comparing the measured object with the reference CAD model

-

Distance measurement

-

Cross-section analysis along with partial or full perimeter measurement

-

Area and volume measurements

These features enable users to generate a comprehensive quality control report (PDF file) directly within the SMARTTECH3Dmeasure software.